Shipbuilding Alignment Services

Precise Alignment of Propulsion, Steering, and Weapon Systems Pays Off

Marine vessels carry unique alignment challenges. Fundamentally, these structures are not rigid due to their size, dynamic forces acting on the hull, and temperature fluctuations experienced during operation. As a result, propulsion, steering, and weapon systems require periodic checks and realignments. Precision alignments performed during a dry dock outage help assure the proper waterborne operation of these systems.

Brunson is a leader in precision alignment services and solutions for the maritime industry. We aid in the construction and maintenance of many critical path components, such as:

- Ships:

- main engines

- reduction gears

- propeller and drive shafts

- support bearings

- stern tubes

- rudder bores

- Submarines

- Periscope

- Optics rail

- Fairing straightness

- Inspection and installation

- Torpedo tray and missile tube

- Periscope

These systems have many interrelated components. The critical geometric relationships between them must be set correctly. Misaligned equipment leaves a vessel vulnerable to a host of issues ranging from bearing vibration and excessive wear in rotating components to strut and hull damage or leakage. The cost of a system malfunction while underway can be staggering.

Whether you are working on new fabrication, a rebuild project, or a vessel that just needs to get back in the water, we can help. The optical instruments we employ are ideally suited for this environment, having measurement accuracies of ±0.001 inch per 17 feet. We can inspect, evaluate and guide the adjustment of components in hard-to-reach places. We have the technology and experience to manage the critical geometric relationships onboard your vessel.

Minimize propulsion components wear, align steering, and refine weapon systems

Learn how precision optical alignment can help increase profits for your vessel.

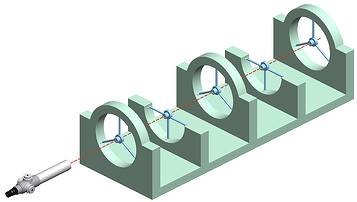

How it works

Let’s discuss bore straightness as an example, since it is an extremely common alignment challenge. In this application, a precision optical instrument (an alignment telescope) is set to the rotational centerline. This is accomplished by orienting the instrument precisely to the engine output shaft or to targets in the near and far bearings. Subsequent measurements are taken to determine deviation from the optical centerline at key bearings or bores in the system.

These measurements are performed quickly and bring significant benefits, including:

- Proper load distribution in support bearings

- Reduced vibration in rotating components (which can damage transmissions, engine mounts, or the boat hull itself)

- Reduced critical failures such as bent or broken shafts

- Reduced main engine crankshaft web deflections for longer engine life

- Improved mesh on reduction gear sets, minimizing unwanted gear tooth stresses and noise

- Proper alignment of periscope components and assemblies

- Efficient weapon deployment through alignment of torpedo trays and tubes

A Name You Can Trust

Brunson has been providing innovative alignment solutions for decades. As a premier manufacturer of high precision metrology instruments and accessories, we use fully calibrated and documented equipment to meet your internal quality standards. The work is documented electronically to show what was inspected or aligned, how it was done, and all the appropriate before and after machine positions.

It Pays for Itself

Customers often tell us that our services pay for themselves within days and weeks, not months or years, with cost benefits continuing to grow after that. Contact us to learn more about how precision machine alignment can improve your marine propulsion, steering, or weapon systems…or schedule an on-site visit to get your equipment running at peak performance.