Power Generation Alignment Services

Shorten Outages and Increase Efficiency with Precision Alignment

The power industry’s turbo machinery is complex, with many internal components and auxiliary systems. Whether they are powered by fossil fuels, hydro, nuclear, or renewables, onthing remains true – precision alignment of the elements in these machines is fundamental to efficient and reliable operation.

Brunson is a leader in precision alignment services and solutions for the power generation industry. Our service team boasts over 30 years of experience with many kinds of turbo machinery and related systems:

- Turbines

- Steam

- Gas

- Hydro

- Aero derivative

- Generators

- Soleplates and bearing pedestals

- Casings

- Pumps

- Reactor vessels

- Spent fuel storage

- Vertical bearings

- Wicket gate bores

- Head cover

These machines have many interrelated components. For reliable and efficient operation, the critical geometric relationships between them must be set correctly. Misaligned equipment leaves your business vulnerable to a host of issues ranging from low generating rates to equipment damage or machine breakdowns. The lost revenue and downtime associated with such interruptions are staggering.

Whether you are bringing a new unit on-line, troubleshooting a difficult machine section, or need support for periodic outages, we can help. The optical instruments we employ are ideally suited for this environment, having measurement accuracies of ±0.001 inch per 17 feet. We can inspect, evaluate and guide the adjustment of components in hard-to-reach places throughout the entire machine train. We have the technology and experience to manage the complex geometric relationships in your machinery.

Protect equipment, reduce outages, yield reliable and efficient power plant operations

Learn how precision optical alignment can help increase profits for your plant.

How it works

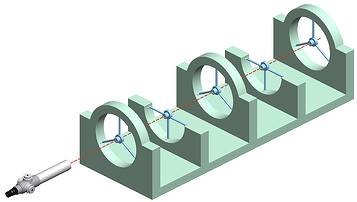

Let’s look at bore straightness as an example, because it is a primary machine geometry to be controlled in power generation. In this application, a precision optical instrument (an alignment telescope) is set to the mechanical rotational centerline. This is accomplished by precisely aligning the instrument to reference datums, such as bearing journals, at the near and far end of the machine. Subsequent measurements are taken on internal components to determine deviation from the optical centerline.

This is one example of a machine profile being monitored and adjusted. These measurements go quickly and bring significant benefits, including:

- Increasing turbine efficiency with accurate diaphragm alignment

- Optimizing the off-line to running (OL2R) condition with thermal growth analysis

- Reducing damaging vibrations and piping stresses

- Identifying root causes such as foundation settling and soft foot

- Reducing premature failures in bearings, seals, shafts and couplings

- Reducing outage downtime

A Name You Can Trust

Brunson has been providing innovative alignment solutions for decades. As a premier manufacturer of high precision metrology instruments and accessories, we use fully calibrated and documented equipment to meet your internal quality standards. The work is documented electronically to show what was inspected or aligned, how it was done, and all the appropriate before and after machine positions.

It Pays for Itself

Proper mechanical alignment is a core requirement for turbo machinery to operate effectively. So it’s not a surprise when our customers tell us that our alignment services provide great value, often paying for themselves within weeks, not months or years, with the cost savings continuing to grow after that. Contact us to learn how precision machine alignment can improve your bottom line…or schedule an on-site visit to get your equipment running at peak performance.